Ask a Simple Question: The Key to Unraveling Confusion in Moisture Testing, Concrete Durability and Refocus on Context

I admit to being a bit of a curmudgeon; well-earned after decades of listening to and experiencing misdirection and false priorities.

I often ask simple questions with the intent to find out IF the subject matter is being dealt with objectively, or is being presented and used in the proper context.

Unfortunately more times than not, the information is not only lacking proper context, the information is intended to "prove" something that isn't within the realm of reasonableness, yet these STILL manage to get accepted if promoted by the right persons/entities.

Testing 1-2-3

Testing and what constitutes testing is one of THE most misunderstood areas in ALL disciplines. An incorrect test, standard or study promoted and/or interpreted out of context is currently a leading cause of why everything continues to become more expensive and when the different professions KNOW they are being pickpocketed, but can't or are technically incapable of protecting themselves, if a "test" or conclusion relieves them of these burdens, right or wrong, these approaches are the easiest to accept and questions are NOT asked for the appropriateness of these acceptances.

ANYONE Can Test ANYTHING

If I compare most current tests for concrete curing, there is little to no differentiation between tests conducted in the 1950's and tests being conducted as we speak.

Most of these tests arrive at similar if not the same conclusions, yet these conclusions do NOT match reality...this is where the simple questions should be asked to separate the chaff from the wheat;

- What is the motive for the study/test?

- What has been determined as "root-cause" to direct the study/test approach?

- Is the test format based on isothermal or non-isothermal conditions? If the subject/material to be studied expected to exist in specific conditions, the base test/study should reflect these conditions.

- What are the test/Study requirements?

These questions are very revealing by how they are answered.

The specifications for slab-on-grade concrete is based singularly on a single property, which is compressive strength at 28 days. As long as manufacturers of flooring and coating materials continue to accept this...nothing changes.

Likewise for specifiers and those who want durable concrete, a singular focus on compressive strength at 28 days, which does NOT directly correlate with any other property that can determine durable concrete, we end up in a hamster wheel of going round and round, doing the same thing over and over and expecting a different result.

IF YOU DO WHAT YOU'VE ALWAYS DONE, YOU WILL GET WHAT YOU ALWAYS GET!

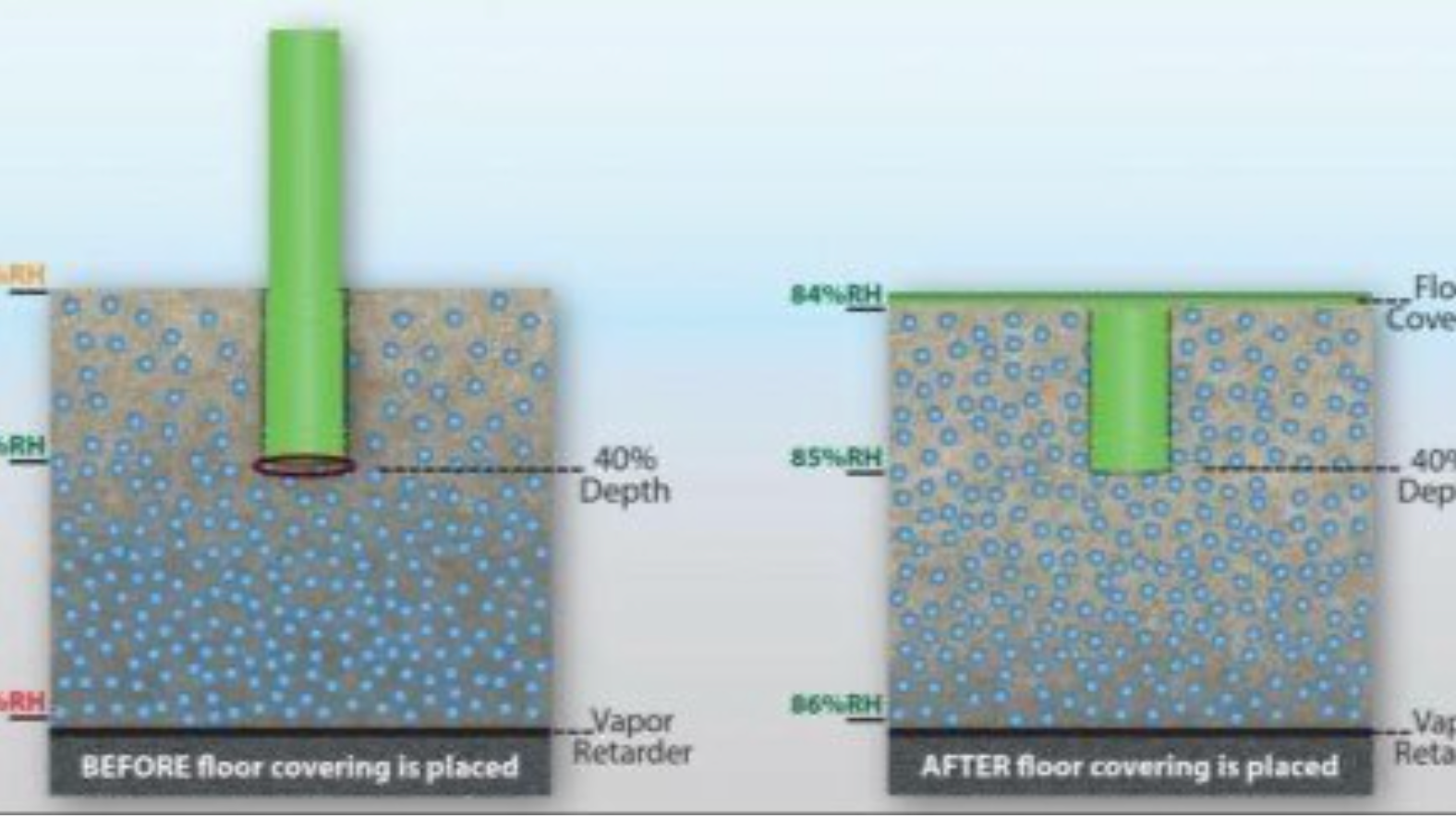

- F2170 - This Standard measures relative humidity, which is simply any moisture in its vapor/gaseous state. This standard is based on the INITIAL drying rate of concrete. The initial drying rate is the excess water used in concrete to be placeable (also called water of convenience). Once this initial drying is essentially completed, actual moisture testing can begin. This caveat is NOT indicated in the standard, yet should be since the premise is based SOLELY on the initial drying rate.

- Relative humidity; this is water vapor present in open areas, irrespective of space volume...this critical point is consistently lost, ignored or unknown to those who WRONGLY require this as a standard to determine the "dryness" of concrete. The assumption, since these studies were not just based on the mix water, but also were tested under isothermic conditions, have NOT been qualified in ANY manner that duplicates field conditions

- Capillary water and gel water; once the initial drying rate has concluded, the majority of moisture volume in concrete has been established to be capillary and gel water. The volume of water in capillaries and gel can be hundreds of time greater than concrete at 100% RH levels. This is easy to prove though gravimetric where a 100% RH will produce almost no weight change in the concrete, indicating the concrete for practical purposes is "dry". It was noted by Hedenblad and others in the Lund Study for capillary water, the volume of moisture is determinable most accurately when measuring the capillary water. The most important difference, even though, once again the study was based on isothermal conditions, this study was conducted to measure moisture content of set and cured concrete, whereas the study for RH Probes was based on the initial drying rate.

- RH Probes in non-isothermal conditions. The promoters of RH probes, other than the companies such as Giatech and others who use embedded humidity measurement devices have NOT been effective or produced useful moisture content information when subjected to field conditions. In each and every situation, the RH probes could not accurately measure moisture content, with even the stated range/measurement limitation of 10%-90% RH. Four different RH sensors provided four different RH measurements, even in isothermal conditions....which is but one reason no one ever sees comparative "apples to apples" comparison of RH sensors, where instead the RH Promoters use "apples and oranges" attempting to justify their results versus other methodologies. In non-isothermal conditions, one constant WAS discovered when comparing shallow RH readings versus the deeper measurements within the F2170 standard; the surface RH was ]routinely lower than 80%, which produces a vastly different quality of concrete where the RH no longer permits cement development. The deeper measurements have a nearly full development of cement content whereas the surface experiences self-desiccation and essentially a concrete surface that is as different from the interior portion of the concrete as the bread crust is from the interior portion of the bread...technically it is still bread, but the characteristics are vastly different from the remainder of the bread. The surface of concrete is also distinctly different from the interior section. This isn't my opinion...it is proven through MANY third party studies.

Constants to Know When Asking the Simple Question

- Are the Studies isothermal or non-isothermal? These test conditions rarely, if ever correlate, yet isothermic conditions are routinely used to determine suitability for non-isothermal conditions..THIS, more than ANYTHING else is responsible for the ongoing non-progress we have in solving most issues.

- Are the studies representative of what the intended environment will be subject to? Unintentionally, the RH Promoters have shown us what happens with concrete, even in isothermal conditions where the concrete surface gradient can have an internal RH of less than 80%, which CLEARLY differentiates the surface from the remainder of the concrete. Even at 80% RH, cement development is estimated to be at a greatly reduced efficiency of 10%. Below 80%, cement formation ceases...so the RH promoters want all of us to believe that the full cement development 1.5 inches is somehow representative and predictive of the surface gradient that is shown BY THEIR OWN DATA to be significantly different.

- ASTM and ALL accepted industry standards are VERY direct, if it isn't SPECIFICALLY stated as the intent, then ANYONE using a standard outside the intent is doing so in a misguided and VERY misapplied way.

Go on, show me where in the F2170 specifically states it measures the moisture content of concrete as is CONSTANTLY advertised by some of the RH Promoters.

And Finally

Two studies, many years apart conducted by The Army Corps of Engineers and the Solar Agency in Florida found that the center portion of the concrete can remain adiabatic.

Why this is important; Adiabatic means the temperature and moisture is unchanging/stationary, it ISN'T freely migrating THROUGH concrete as we are all taught to believe....when conditions were elevated concrete has higher moisture content than on-grade concrete with or without non-permeable steel pans...there is NO underlying moisture source for these concrete floors.

Where migration of moisture is misinterpreted by those with no experience in the waterproofing, roofing or restoration fields is that water can transport materials by diffusion, with those that do not understand the differences claim the reason the contaminants from another location PROVES the moisture migrated, even though the water has remained stationary. We conducted such experiments in high school where dyes and salts would "migrate" from one container to another or even within the same container by diffusion and even convection, but NOT by "moisture migration".

The other constant...although many have claimed otherwise, water is in its densest form as a liquid...therefore water vapor CANNOT migrate through liquid water, which is present in capillaries and gel water...so any moisture that enter from say the bottom, is blocked by capillary water and gel water..the capillary water remains non-moving for MANY years...but water WILL evaporate from the surface of the capillary and gel water. Here is where things get REALLY interesting; several researchers have expressed frustration that when cutting or breaking concrete, they cannot detect the migration of water and end up using gravimetric to determine moisture content. As is the case with so many others...because they can measure moisture going into the underside of a concrete specimen and measure moisture coming out of the top of the concrete, the ASSUMPTION is that this is moisture migration, even though it is much simpler than that...this is moisture moving in and out of the various external gradients of the concrete. NOT ONE SINGLE RESEARCHER HAS TRIED TO OR BOTHERED TO MEASURE NET GAIN AND LOSS....measuring ONLY the gain or loss.

Moisture moves in and out of a concrete surface, but this has been ignored..measuring ONLY in a single direction. THAT is why moisture content is measurable with gravimetric but not visible because the water ISN'T "flying" through the concrete.

Certification of Moisture Testing

Until the schools and agencies start teaching the basics of concrete and the chemical influences and the five forms of moisture within concrete, my criticism of what is taught about measuring concrete moisture remains unwavering. In my opinion, what is being taught is as much a negative as a positive...using circular logic to justify the respective curriculums.

NFCA has taken the first bold step into proper education.

From Logical Fallacy: "Circular logic, also known as circular reasoning, is a logical fallacy where the conclusion of an argument is assumed in the premises. In other words, it occurs when the reasoner begins with what they are trying to end with, creating a "circle" in reasoning. For example, saying "Everyone must obey the law because it’s illegal to break it" is circular reasoning, as it uses the conclusion as a premise. This type of reasoning is often seen as a pragmatic defect in an argument, as the premises require proof just as much as the conclusion does."

Now, let's apply this to the flooring industry: "we use this standard because everyone else uses it."

When I ask what is the reason you are using this standard as a warranty requirement. This straight forward and simple question rarely if ever gets a direct answer; instead, circular logic kicks in yet again, wash, rinse, repeat....