The Importance of testing the concrete Floor Surface - It's NOT my opinion, It's based in fact!

It still amazes me how there is even a discussion that the lowest volume of moisture, tested 1 1/2-2 inches into the concrete takes precedent over surface testing, where the floor actually fails, due to liquid moisture, the largest volume of moisture in concrete and the only way alkalinity or other compounds can damage a floor.

The Concrete Surface IS different from the rest of the concrete

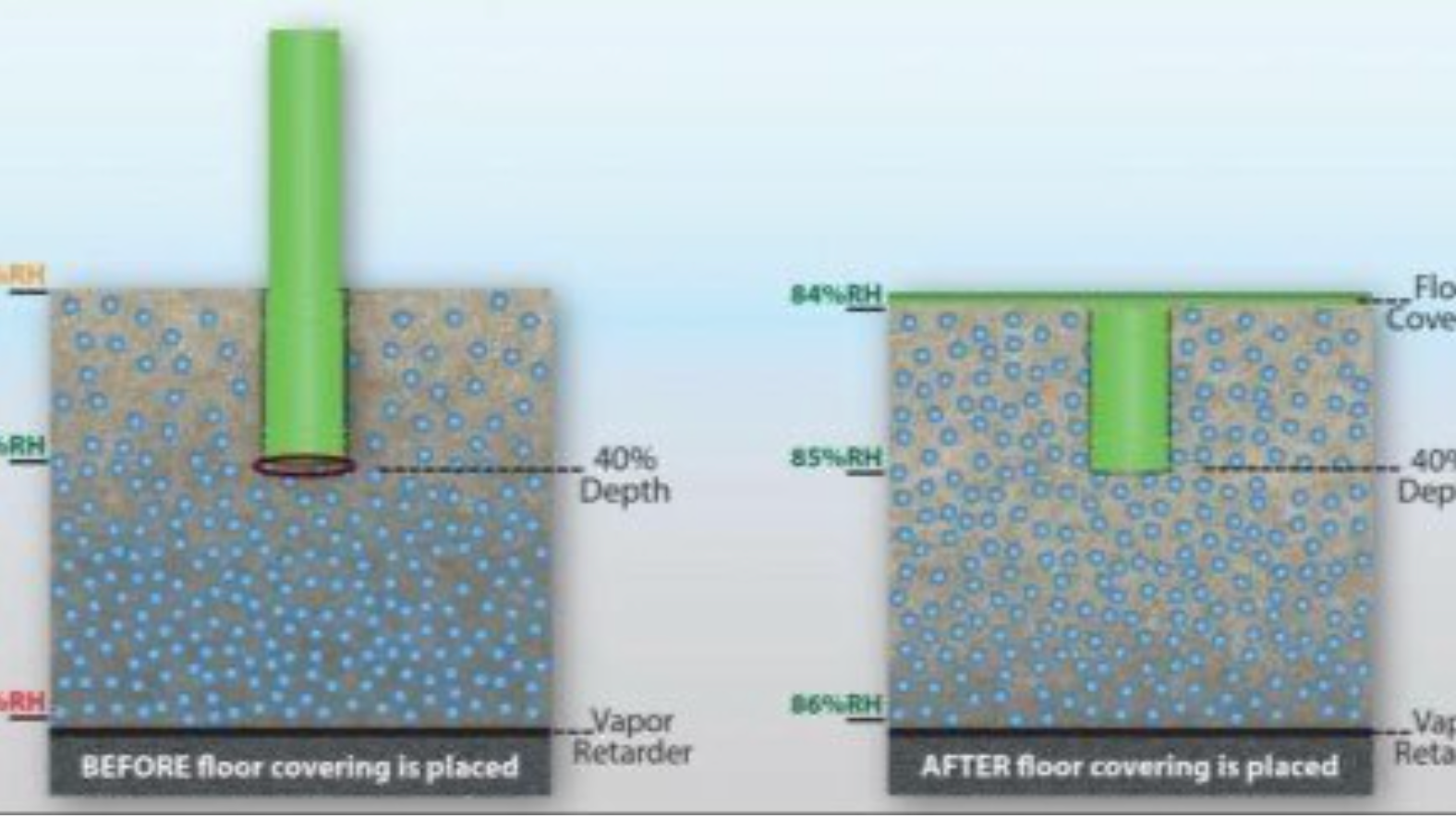

I used the graphic where RH probes were trying to establish a narrative that uncoated concrete in this study had a low RH in the surface, with the RH being higher in the lower regions of the concrete, then later on it would "equalize". My question is, when hasn't this happened, and further, statistically nearly 100% of concrete foundations will re-equilibrate, but statistically less than 1% of them fail.

NEWSFLASH: This is EXACTLY why surface testing is critical!

When the RH of concrete drops below 80%, cement formation ceases; in the meantime, in this same graphic, it shows the cement formation inside the concrete (where the RH Probes are embedded) is in a desired RH threshold. Even at 80% RH, cement formation is very slow and inefficient. With ALL new concrete, to get a durable surface and in turn a durable concrete, the RH MUST be maintained at a very high RH.

Once the cement formation is interrupted, there is a permanent loss of available cement formation. I often saw this in petrographic analysis where I would request the petrographer estimate the percentage of unhydrated clinker. NOTE: "clinker" is the material designed to become dampened sufficiently to produce cement. "Cement" isn't cement until it hydrates, otherwise it is simply another form of "dirt", giving no beneficial functionality to the end product.

Claim Versus Fact

There is a terrible assumption that leads to claims of "properly cured concrete" producing a homogenous solid. Those claims are based on assumptions, NOT fact....I know because for many years I was also under that assumption, until more sophisticated testing and research revealed the fact that it is a rarity that concrete can be "properly cured" in the manner in which it is represented. Most curing protocol are over 100 years old...and the cement/concrete used 100 years ago (even 25 years ago) is MUCH different than the concrete we use today, yet adjustments to our procedures for curing concrete have NOT kept up with the constant changes cement AND concrete have undergone in the past 100 years.

Fact Versus Claim

One of THE most telling facts are those that undo the claims made about the importance of moisture in concrete and what that moisture does.

Those promoting RH Probes ignore the FACT that even a small amount of liquid water has much more volume than an area with a 100% RH - at ANY temperature. NOTE: In a cubic meter of air space, it would take more than 264 gallons of water to fill that space, yet it would take less than 2 ounces of water to produce 100% RH.

At 100% RH, the maximum volume of water in vapor/gas form is less than 200 grains per cubic foot of space, the maximum amount of vapor pressure (for an uncoated concrete surface) is 1.2 psi and is even lower once a floor covering is installed since one of the pressure influences (RH differences from the concrete surface to the ambient conditions) is removed. NOTE: The 1.2 psi is based on uncoated concrete where the differences in temperature AND humidity are involved, in reality is the pressure is substantially lower than the 1.2 psi maximum. A standard adhesive has 40 times more bond strength than can be exerted by the highest level of vapor pressure.

The narrative of RH measurements has altered, as questions have come up.

First the advertised claim was "RH Probes are the most accurate method to measure the moisture content of concrete", along with claiming to be a "predictor" of future moisture claims, neither of these claims are accurate. Most RH promoters now state what is described in ASTM F2170, which is the measurement of RH within the concrete, NOT moisture content.

There were statements made by some of the "technical experts" of RH Probes that claimed if a salt solution becomes saturated, the RH will return to 100%. Even worse, these "experts" claimed water vapor can transport alkaline salts.

The FACTS are readily available by three well-established examples: The hydrological cycle of the earth, the distillation process for purifying water and visible efflorescence on a concrete surface. ALL three examples prove that solids, alkalis, etc. are transported and carried by water in a liquid form, but as the water is vaporized, the solids are left behind. Yet these basic facts were ignored (or unknown) to these "experts".

Even worse, the building sciences have established a logical priority when dealing with excess moisture. The priorities are ALWAYS: 1. bulk water, 2. capillary water and 3. water vapor...in that order. Yet the flooring and coating industries are upside down in that priority.

With concrete, the initial bulk water is the water of convenience, where most of the bulk water is reduced by the very properties that make concrete such as useful building material; the bulk water begins to evaporate and much of it leaves of its own accord as "bleed water".

After the bleed water is no longer visible, the finishing operations can begin because the majority of the water in concrete at that time is "capillary water".

Capillary water is the highest moisture volume in concrete after the bulk water is lost. Capillary water is NOT measurable using a humidity measurement of ANY type. Capillary water IS measurable with an electric impedance meter. So the greatest volume of water, when relying on an RH Probe remains unmeasured.

As indicated in the above graphic used by the RH Promoters, the concrete surface can and usually will self-desiccate. Cement formation ceases when the RH falls below 80%. THIS changes the areas of the concrete that have prematurely "dried out" and are substantively different from the area(s) that will be measured by the ASTM F2170 procedure. NOTE: If you really think about it, here is what is being prioritized by using RH Probes: ignore the area of concrete that has higher permeability, porosity and great moisture volume and where the flooring/covering is actually applied to and has problems and let's instead measure the buried portion where none of the "bad stuff" is affecting the concrete!

This is the confusing part and why the assumptions exist that "properly cured" concrete will produce a consistency throughout the concrete matrix.

When the water is applied to cure the concrete, ideally it will hydrate ALL the cement.

Instead, as the water is consumed by the cement, the alkalinity present in the surface, greatly affected by elevated temperatures, lower humidity, air movement and sunlight will begin to concentrate.

When alkalinity concentrates, it reduces the measurable humidity. The most voluminous alkaline salt is typically sodium hydroxide. Sodium hydroxide suppresses the solubility of the newly formed calcium hydroxide, even as the NEEDED RH levels decrease. This reduces the "contactable" area normally available for moisture. This is exacerbated by rising temperatures.

This discovery of inadequate curing was discovered by accident rather than intent.

Many studies have shown that water ponding may not penetrate into the concrete where it is needed and as a result, the self-desiccation (autogenous desiccation) can manifest itself much earlier than anyone could have imagined.

In several studies, independent of each other and likely not aware of the other studies, it has been determined that the concrete surface develops a gradient, which coincides with the self-desiccation. This gradient was consistent with each study, determining the gradient to be 19-25 mm (0.75-1.0 inch) of the concrete surface. This self desiccation was noted to occur within the first 2-3 weeks after concrete placement.

The graphic used by the RH promoters even PROVES this gradient exists, even under laboratory conditions where cement formation ceases as the RH falls below the 80% threshold.

This was unintentionally confirmed in a study conducted by TTI (Texas Transportation Institute) where Dr. Zollinger took two concrete samples, one air cured for 7 days and the other water cured for 7 days.

The lower compressive strength of the air-cured as compared to the water cured sample surprised no one; but what WAS surprising is the 7 day water cure, where the top one inch of the concrete was evaluated independently from the remainder of the concrete, was a full 20% lower in compressive value as compared to the fully intact concrete.

This helps to explain the industry assumption of a uniform, homogenous concrete; even compressive strength tests helped to "hide" these differences since the compression strength tests are based on the breaking of the sample. With a slightly weaker surface, there may be some unnoticed crushing, but this crushing effect is outside the capacity of the standard compression test is measured ONLY at time of breakage.

I believe if all concrete samples were evaluated in the manner as devised by TTI, there would be a shockwave throughout multiple industries.

THIS is Why Electrical Impedance Meters (based on Independent, Third Party Study under field conditions) are critical, not only for the actual measurement of moisture content, but NEEDED immediately before and during installations. IT is the SURFACE that is distinctly different from the remainder of the concrete.

Testing At Time of Installation - The Missing Link

No testing hours or days prior to an installation is any indication of whether a coating/flooring installation will be successful. Too much can happen between the time of testing and what the concrete surface may be exposed to in the interim.

Older concrete in particular can present MANY challenges and way too often I've heard complaints where a former flooring/coating was removed after successfully performing for many years, only to have the subsequent floors fail multiple times. This is the genesis of more assumptions.

Concrete can be in dynamic equilibrium with the moisture content with an existing floor/coating, yet once the coating/floor is removed, the concrete surface is now exposed to a "new" moisture source, the ambient air.

The most profound example of this happened in 2023. I had given a presentation to a Northern California Installation Group where they asked me why older concrete was more of a problem than newer concrete even though the moisture readings were lower (lower according to RH Probes).

I explained that salts tend to collect at the surface and in extreme cases have caused ASR damage of led to "Slab Sweating Syndrome". If a flooring/coating is over a surface such as this, but not a particularly aggressive form of salt that will damage a coating or flooring, nothing will happen, until they removed the existing floor/covering. At that time, the salt laden surface will begin to adsorb moisture and the longer it sits, the more likely the moisture content will increase.

NOT 3 months later, David Daniels was giving a lesson on how to properly use a Tramex Concrete Meter. This was the exact same facility where I warned the installers about older concrete. The area was a 42 year old warehouse. The area they picked was measured, with what appeared to still be covered with a curing agent. They measured over the curing compound with a measurement indicating 1.9% moisture content, which should be expected with a healthy older concrete. They ground off the coating and measured again, with the moisture content of 1.9%.

After walking around discussing other aspects of testing the group returned, placed the meter on the same area and the moisture level had increased to 4.3%!

They tested again to see if there was something that caused this jump and the reading remained elevated...and this was only 10-15 minutes after the second test of 1.9%.

I have seen this happen many times before, but not to this extreme. THIS is where data gathering and the timing NEEDS to be established to determine root cause.

If the coating had been removed and not tested until the next day, the assumption would have been this moisture "rapidly migrated" up from inside the concrete, when in reality, this was 100% sourced by the ambient conditions.

This is why I am so pedantic about procedure and methodology. If you miss one thing, you can miss everything!

For Slab Sweating syndrome, older concrete, and self desiccated concrete surfaces what value would an RH Produce for a flooring or coating manufacturer?

Conclusion

Nearly every problem with concrete begins on the surface and within the gradient. In fact, it would be difficult to name deterioration of concrete that DIDN'T originate from the surface, which is why proper curing is critical, yet proper curing isn't being done and we need to give that the highest priority. It is entirely possible that through some modifications, even the problematic Type IL cement can be "corrected" to produce a satisfactorily durable concrete.